Metrology RoomPrecision and control

to guarantee our production

In addition to the production departments, OMD has a controlled Metrology Room , featuring a large instrumentation that is continuously and constantly updated. Thanks to this important equipment, it is therefore possible to carry out each measurement with the highest precision, in order to guarantee the maximum quality and conformity of each process.

OMD ‘s Metrology Room represents a fundamental and strategically valuable asset for the company and its customers, who can always count on rigorous and accurate production control processes.

Metrology RoomOur equipment

GLEASON 300 GMS involute meter

3D precision inspection system with scanning probe, linear pass for gear involute inspection. ISO17025 certification of A2LA® quality systems adopted by Gleason.

GLEASON SIGMA 175GMM involute meter

3D precision inspection system with scanning probe, linear pass for gear involute inspection. ISO17025 certification of A2LA® quality systems adopted by Gleason.

“Mitutoyo Roundtest” roundness meter

Compact table-top instrument for the most stringent demands on measuring accuracy for cylindricity control. Quick and easy manual centering and leveling of the workpiece. Precise and frictionless rotation. Thanks to the air-supported table. For adequate responses to high expectations.

Profilometer “Mitutoyo Contracer CV-2000”

The standard for fixed profilometer measurement. For efficient use in every aspect, both on the production line and in the testing room.

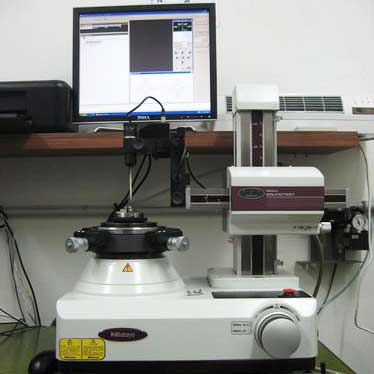

Mitutoyo Sourftest SV-400 digital roughness tester

for checking planes and holes.

Digital profile projector

for precision measurement.

OMD

Gears and mechanical processing

Are you interested in our products and processes? Have you seen one of our services that might interest you?

Contact us to know more!

It's easy, we won't send you junk mail and we will only use your contact to respond to your requests.

Error: Contact form not found.